Custom Solar-Powered Emergency Safety Showers for the Mining Industry

PETRO designed and built custom solar-powered emergency showers and eyewash stations for a mining client — delivering compliance, safety, and off-grid reliability.

Do not underestimate the importance of clean fuel. It will keep your engines running and save your business hard-earned money by minimising break downs and maintenance costs. A quick breakdown of the setup:

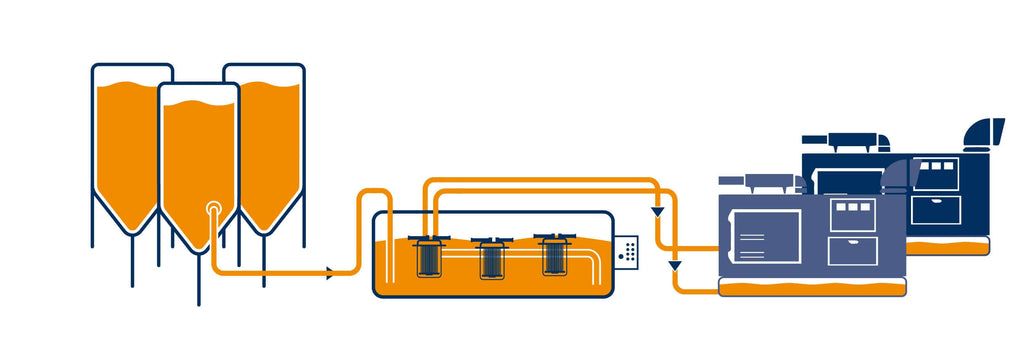

This PETRO Liquitainer 16,000 litre Self Bunded Fuel Tank is equipped with a cleverly configured Pumping and Filtration assembly to decant fuel from a 400,000 litre bulk storage facility, filter the fuel for particulate and water and finally pump it out into secondary storage tanks for daily use in power generation.

A Detachable Pump Bay Housing is linked to the Liquitainer, resulting in a modular, scalable solution.

The PETRO designed PLC Control Panel allows for fully automatic and Manual use with a two-pump connection for back up purposes.

PETRO Self Bunded Fuel Tanks are built to last and carry all the Standards and Certifications needed worldwide.

Watch the VIDEO below for more detailed information on the specifications of the custom installed equipment.

Join our Sales Manager, Mark, as he takes you for a walkaround of one of our small but specialist projects.

This PETRO 16,000 litre Liquitainer Tank is the perfect solution for keeping your fuel clean and your engines running, so you can avoid the costs of preventable breakdowns and maintenance.

Equipped with an intelligently designed Pump and Filtration Configuration, this solution takes the guesswork out of fuel distribution and decanting with the system being fully automated and reactive. The Pump and Filtration Configuration transfers fuel from a bulk storage tank into the LT16 filtration unit, filters the fuel for particulate and water, ready for distribution into smaller, secondary storage tanks.

Designed and fitted by PETRO Industrial, the PLC Control Panel fitted to this Liquitainer is capable of operating both automatically and manually, allows for a dual pump connection for backup purposes, and ensures ultimate safety with an alarm system. The PLC Control Panel also allows you to view which pump is running, as well as its flow path and pipe work. Taking full control has never been easier.

The Self Bunded Tank itself is comprised of a detachable pump bay and PETRO Liquitainer 16,000L Self Bunded Tank. This modular design allows the solution to be scaled up and down to suit the consumption needs of your operation. This just demonstrates how versatile PETRO’s Liquitainer Self Bunded Fuel Tanks are; suitable for any job, anywhere in the world–even the Marshall Islands!

Don’t underestimate the importance of clean fuel and contact our team of hand-picked service specialists today!

Contact PETRO Industrial today for more information, or to see how a tailored self bunded fuel tank solution can add value to your business today!

-

Video Transcript:

"This one’s going to the Marshall Islands, which is far Northern Pacific, probably the most remote place in the world other than Antarctica. We’ve got it hooked up to the test tank at the moment, we’ve been processing a heap of test transactions to make sure it all works properly.

What else can I say? This is it, it’s very exciting stuff, it’s a really smart system. Everything here was done in-house at PETRO Industrial, from the PLC programming, to the design, to the build. It’s been fully wet-tested, passed all QA, now we’re going to pull it apart, clean it up and send it off to the customer.

What this tank is doing is cleaning fuel. It’s taking fuel off a bulk tank, pumping it through a set of filters back into the tank itself. Later on the valving will switch automatically and it will transfer fuel out to a secondary tank.

Just going through the HMI interface, we have set up the system so we’ve got manual modes that we can run independently of the automated system. We have auto modes so we can select pump one or pump two. We have our process that shows on the HMI which will show which pump is running its flow path with the pipe work.

We’ve got alarms. We’ve got an alarm page, should something go wrong we’ll hear an alarm page.

The way this system is set up is if a pump fails, the second pump will kick in automatically, if both pumps fail it will come up flashing with alarms. It’s a very clever system.

This is the interface; we have a fully manual system on the board so we can take all of this out of play, should the PLC fail we can switch it to manual and run it in a fully manual mode.

What we have here is a detachable pump bay. We manufacture these at PETRO Industrial so we can fit these to either end of the tank; use them as a standalone weatherproof enclosure for remote jobs. This one is attached to a 16,000L Liquitaner tank. This tank is 6mm back to back-to-back plate steel, floor and roof, so it’s super strong with UL142 certified.

As you can see, it’s a solid construction designed to last for a long time on the market.

What we’ve got here is a level switch or day tank control probe.

What’s happening, this sits inside our tank here.

As this float actually will sit up there in the fuel, when the float drops, which is called make on fall, this will start the pump.

This float here, which is make on rise, will actually go up and stop the pump.

Then we have a failsafe float here which will turn everything off when it rises.

These are made to order for the job.

We have a secondary one on the floor here which is going in another tank, which is called a settling tank.

So that will control the transfer out of this tank to a secondary tank.

Here we have part of the PLC, here and here.

This is the display, this is the PLC unit.

Over here we have the relay system so it can run manually.

If you go into the front of the board, we can actually run it on the PLC or we can switch it into fully manual mode and then we can start and stop the pumps by manually opening the ball valve.

Its got full manual redundancy away from the PLC should there be a problem.

We’re looking at these three-way electrically activated ball valves.

It’s got that indicator here which shows the positions; this is in a closed position.

In the closed position this valve is facing into our tank.

If it turns green it’s in the open position, which means it’s now exiting our tank.

You’ll notice there’s a crank handle here, this is so we can actuate the valve manually if we put the system into full manual mode.

There’s a secondary valve over there on the other line, which is the suction line.

This is the fill line of the direction coming from the pumps into or out of the tank.

What is also happening in here, we’ve got solenoid valves hidden right at the back.

These solenoid valves allow the fuel out of the pumps into the lines.

So when we switch between the filter units they’re powered to open, so the power comes on and directs the fuel to either bank one or bank two depending on which is the primary pump and which is in play at the moment.

So what’s happening in the filtration; firstly we’re filtering for particles.

Secondly, we have water absorption canisters on here to take out water out of the fuel."

PETRO designed and built custom solar-powered emergency showers and eyewash stations for a mining client — delivering compliance, safety, and off-grid reliability.

Discover how PETRO designed a custom mobile 4,500L solar-powered fuel storage and dispensing solution for a mining client — complete with smart tracking and cloud-based reporting.

The iPETRO Link Gateway is the ultimate bridge between your fuel storage and dispensing systems and the powerful iPETRO VMI Cloud dashboard. Engineered for seamless integration and total visibility, this device consolidates data from any Fluid Management or Automatic Tank Gauging (ATG) system—no matter how remote or distributed your sites are.